The NUK-HP®

is a high-pressure natural circulation boiler operating by the gravity circulation principle.

Therefore circulating pumps are not required to operate the NUK-HP®. Boiler water is used as the heat carrier. The water is evaporated in this boiler within a hermetically sealed circuit. The steam flows to the heat exchanger and the condensate flows by gravity back to the boiler.

| Application/Advantages |

Application

Food industry for Distillation and fractioning of fatty acids, esterification of fatty acids, distillation of glycerine, deodorising edible oil, fat splitting. Applicable in all process heating plants in which plant-relatively a natural circulation can be implemented in the heating system.

Efficient, non-toxic processing heating system. Very low flow resistance in the vertical evaporator pipes to guarantee high water circulating rates. Low radiation load in the combustion chamber and a large convection heating surface. Steam bubble formation in the pipe system is therefore very low. Controlled heat transmission at the heating surfaces is guaranteed and a high combustion efficiency is achieved.

You find further technical information on every type of heater in the Download Area of our Internet site.

| Production/Equipment |

Equipment

The boiler equipment is for operation without supervision (acc. PED and EN 12952). Pressure, boiler-water minimum level and flue gas temperature are permanently monitored by a safety control system.

Control

The capacity can be controlled by different controlling systems.

- Pressure control:

The capacity of the NUK-HP® and the saturated steam pressure is controlled independently product temperature (e.g. vegetable oil). - Cascade control:

The capacity of the NUK-HP® is controlled according to product temperature (e.g. vegetable oil). The saturated steam pressure is adapted in a defined range of control according to the heat requirement of the heat exchanger (e.g. vegetable oil) in the product temperature.

Burner

The NUK-HP® can be equipped with burners for light oil, heavy oil, bio diesel, natural gas, liquid gas, bio gas, or with two-component burners. The choice of burner depends upon the boiler capacity, the fuel and the demands expected of capacity control. The capacity can be controlled by different controlling systems: 2-stage: high / low / off or modulating

Permanent Monitoring

- Water level low

- Steam pressure

- Flue gas temperature

- Burner control

You find further technical information on every type of boiler in the download area of our internet site.

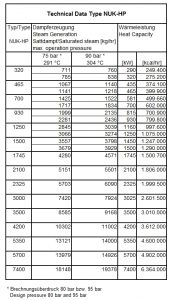

| Technical Data |

* Design pressure 80 bar or 95 bar

You find further technical information on every type of boiler in the download area of our internet site.

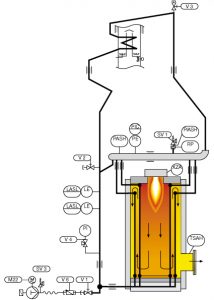

| P+I Diagram/Schema |

| M 22 filling pump V 1 filling and drain valve V 2 check valve low Level V 3 flushing and venting valve V 4 pressure gauge valve V 6 non-return valve PI pressure gauge SV 1 safety valve SV 3 safety valve for filling pump WT heat exchanger TE temperature sensor TIC temperature controller PASH pressure limiter PE pressure transmitter PIC pressure controller RP rupture disc PIASH pressure indicator-alarm switch LE low level water electrode LASL low level switch XZA flame sensor TSAH temperature limiter-flue gas |

You find further technical information on every type of boiler in the download area of our internet site.

Deutsch

Deutsch Русский

Русский Français

Français