The Thermal Oil Heater THZ/ GKV/H

The GekaKonus® Thermal Oil Heater type THERMOMAT® is a forced circulation heater of 3-pass design for organic high temperature heat transfer media on mineral or synthetic basis. It consists of a cylindrical combustion chamber, formed by closely bended pipes. This principle ensures that a defined heat transfer is achieved at any point of the heating surface. Forced circulation, and thus the flowing speed, is ensured by measuring and monitoring the volume flow.

| Application |

In all industrial heating processes e.g.

- Industry for rubber, plastic and flooring

- Metal industry and surface finishing

- Soap and detergents industry

- Food industry

- Textile industry

- Bitumen and tar processing industry

- Chemical industry

- Building materials industry

- Wood industry

- Paper and cardboard industry

- Laundries

| Advantages |

| Production/Equipment |

Equipped and produced in conformity with the European Community technical rules (PED 2014/68/EU), and other world-wide acceptance organisations (e.g. SQLO, GOST-R, RTN, ASME).

Equipment

The controls and safety elements of the GekaKonus® Thermal Oil Heater Type THERMOMAT® are comply with the stringent regulations enforced in European Community and DIN 4754.

Control

The flow safety device is a very important element as it measures and monitors the minimum heat carrier flow rate and shuts down and interlocks the firing system if the flow rate drops below the minimum value. The safety temperature limiters in the outlet and flue gas prevent an inadmissible rise of the outlet and flue gas temperature.

Fuel

All commercial gaseous or liquid fuels can be fired, e.g. heavy oil, medium oil, high speed diesel, bio diesel, liquid gas, natural gas, bio gas.

You find further technical information on every type of heater in the Download Area of our Internet site.

| Technical Data |

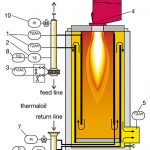

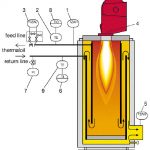

| P+I Diagram/Schema |

2 Temperature sensor – feed line

3 Flow monitoring device

4 Flame monitor

5 Safety temperature limiter – flue gas

6 Temperature sensor – return line

7 Manometer – feed line

8 Temperature controller – feed line

9 Temperature sensor – return line

10 Manometer – return line

You find further technical information on every type of heater in the download area of our internet site.

Deutsch

Deutsch Русский

Русский Français

Français